Zero Gravity Tool Balancers and Part Manipulators

Zero Gravity Arm for Die Grinder

The Die Grinding Arm allows precision die repair and features: A piloted carbide deburring tool allows the precise removal of welds, magnetic base, and a reach from 22 to 67 inches.

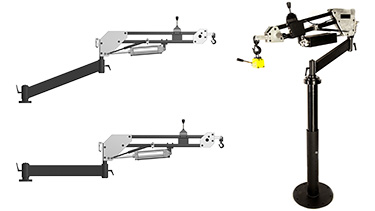

Manipulator Arm for Steel Plate Parts

The Part Manipulator Arm has capacity to lift up to 200 lbs, with a max reach up to 100 inches. It operates in small areas to load and unload tools or hold and position parts.

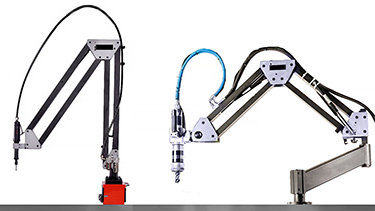

Hydraulic Arm for Tapping 2in. Holes

This arm features a semi-automatic tap lubricator system, taps from .25 to 2 inches in mild steel, max torque of 811/162 ft/lbs, size 4 quick change chuck, and a three year warranty.

Pneumatic Arm for Tapping Holes

This arm features a working range of 11 to 34 inches, taps from 0 to 9/16 inches in mild steel, max torque of 28 ft/lbs at 90 psi, size 1 quick change chuck, and a three year warranty.

Zero Gravity Part Manipulator Arm

The Zero Gravity Part Manipulator Arm/Lift Assist device takes care of lifting and moving materials where standard cranes or hoists will not work. The part manipulator arm is also available in a variety of weight range capacities and reach requirements.

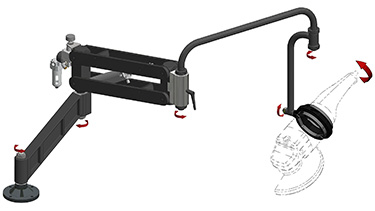

Zero Gravity Arm with Gimbal Mount

The Gimbal mount adds 4 additional rotation points to an end effector on the arm while counterbalancing the tool weight. When a tool is mounted into a Gimbal on the Zero Gravity tool balancer arm, the combination provides a smooth and almost weightless application.

Zero Gravity Arm for Grinder

This torque arm pneumatically counterbalances the weight of heavy tools creating a zero gravity effect. The gimbal can be customized to fit any tool and allows the operator complete freedom of movement.

Zero Gravity Arm with Hook

This zero gravity arm is ideal for reaching into confined areas where traditional lifting devices, such as jib cranes, cannot go. Features include 38-56 inch range, vertical range of 30-50 inches, and cart, table, pedestal mount options.

Tapping or Drilling Tool Balancer

These arms are available in pneumatic or hydraulic power and are ideal for tapping, drilling, reaming, chamfering, deburring, and countersinking. Features include: 28-78 ft/lbs. max torque, 11-72 inch working range, with several accessories, mounts, and holder options.

Ergonomic zero gravity tool balancers are the perfect solution for applications with suspended tools such as pneumatic tools, grinders, sanders, buffers, drills, torque wrenches, rivet squeezers and hand tools. Zero Gravity Arms are used when the precision and control of a pneumatic balancer or spring balancer is just not enough. Our ergonomic Zero Gravity tool balancer technology enables the most versatile tool in existence - the human hand guided by the human mind - by providing ways for workers to control objects in their environment with less exertion and more precision.

Why Choose a Zero Gravity Tool Balance Arm?

- Reduces workplace injuries

- $125+ billion spent in the U.S. annually on worker injuries

- Shoulder injury cost to employers $80-120k in direct costs

- Injury = waste. Best place to save money

- Executives report return of $3 or more for each $1 spent improving workplace safety

- Increase worker productivity

- Tool balancers allow heavier, more powerful, faster tools

- Can use combined or multiple tools

- Can use tools for longer periods

- Decrease task time

- Better employee utilization

- Accommodate aging workforce

- Lengthen career of duty-restricted employees

- "Guiding, not lifting"

- More efficient shift organization

- Quality

- More precision - using fine motor skills, not gross

- "High touch and high exertion -don't go together"

- Zero Gravity Tool Balancers hold tools or parts from 8 to 60 lbs.

- Grinders, sanders, buffers, drills, torque wrenches, rivet squeezers, etc.

- Lift adjustment allows the arm to cover wide weight range and provides assisted lift (force multiplier)

- Proprietary line of gimbals allows wide range of tools to be maneuvered with ideal freedom of motion

- Wide variety of installation options - stands, slides, carts

Zero Gravity Tool Balancer / Part Manipulator Documents

Ergonomic Partners provides zero gravity tool balancers; serving clients from coast to coast, Canada, Mexico, and especially focused in the states of Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.